Clamps & Accessories

Panel Glue-Up Clamps & Accessories

|

||||||||||||||||

Note: Wood not included |

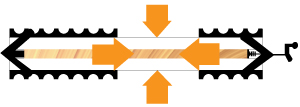

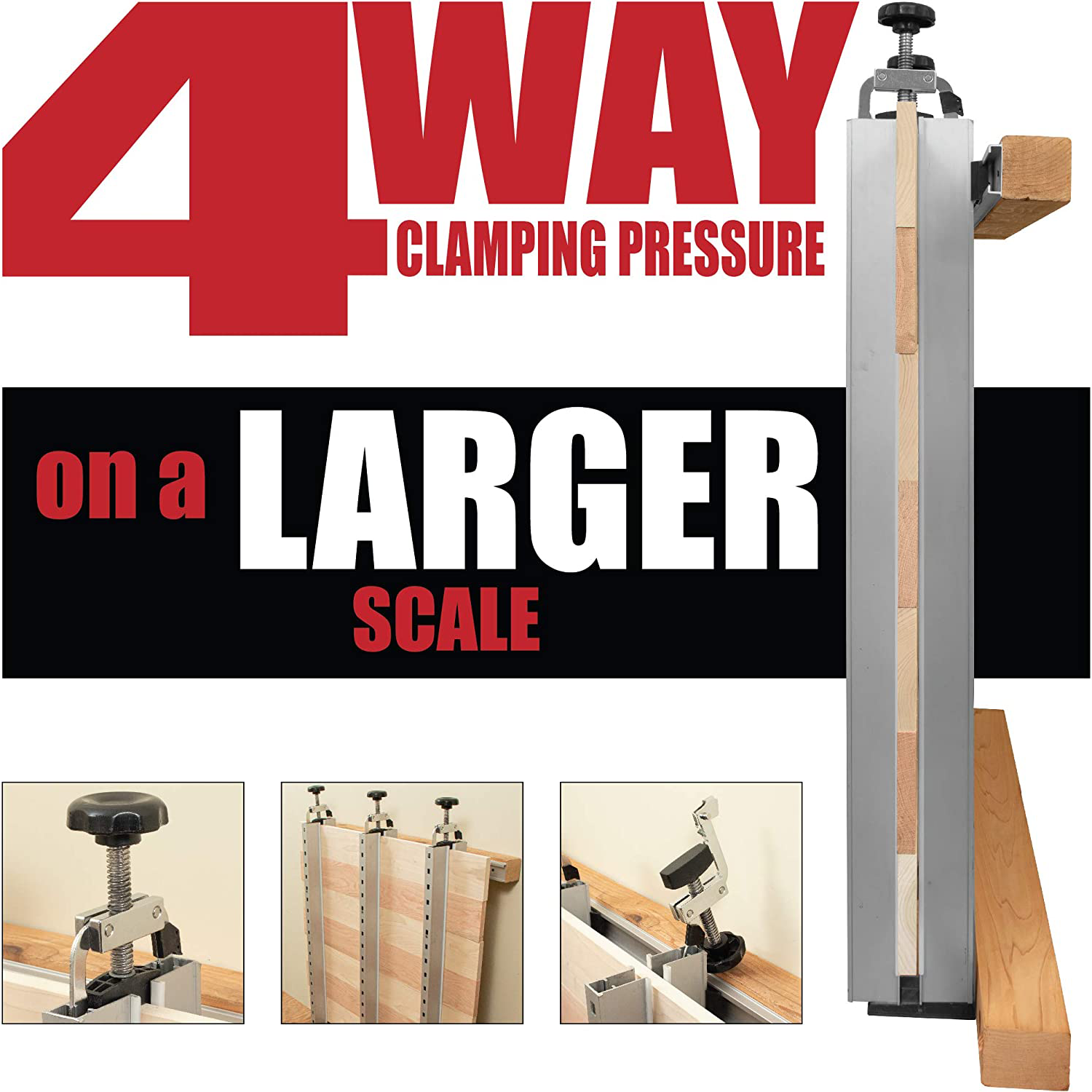

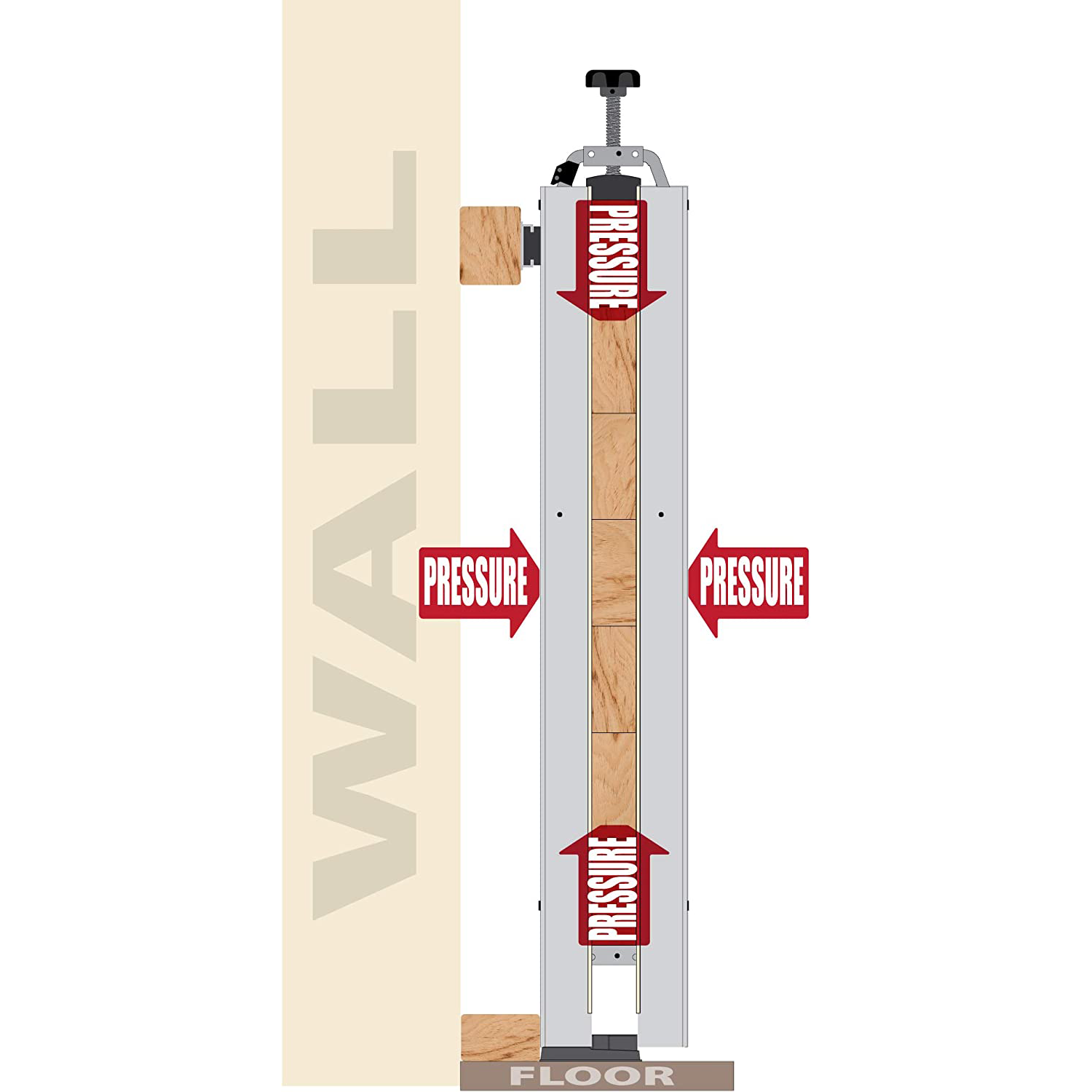

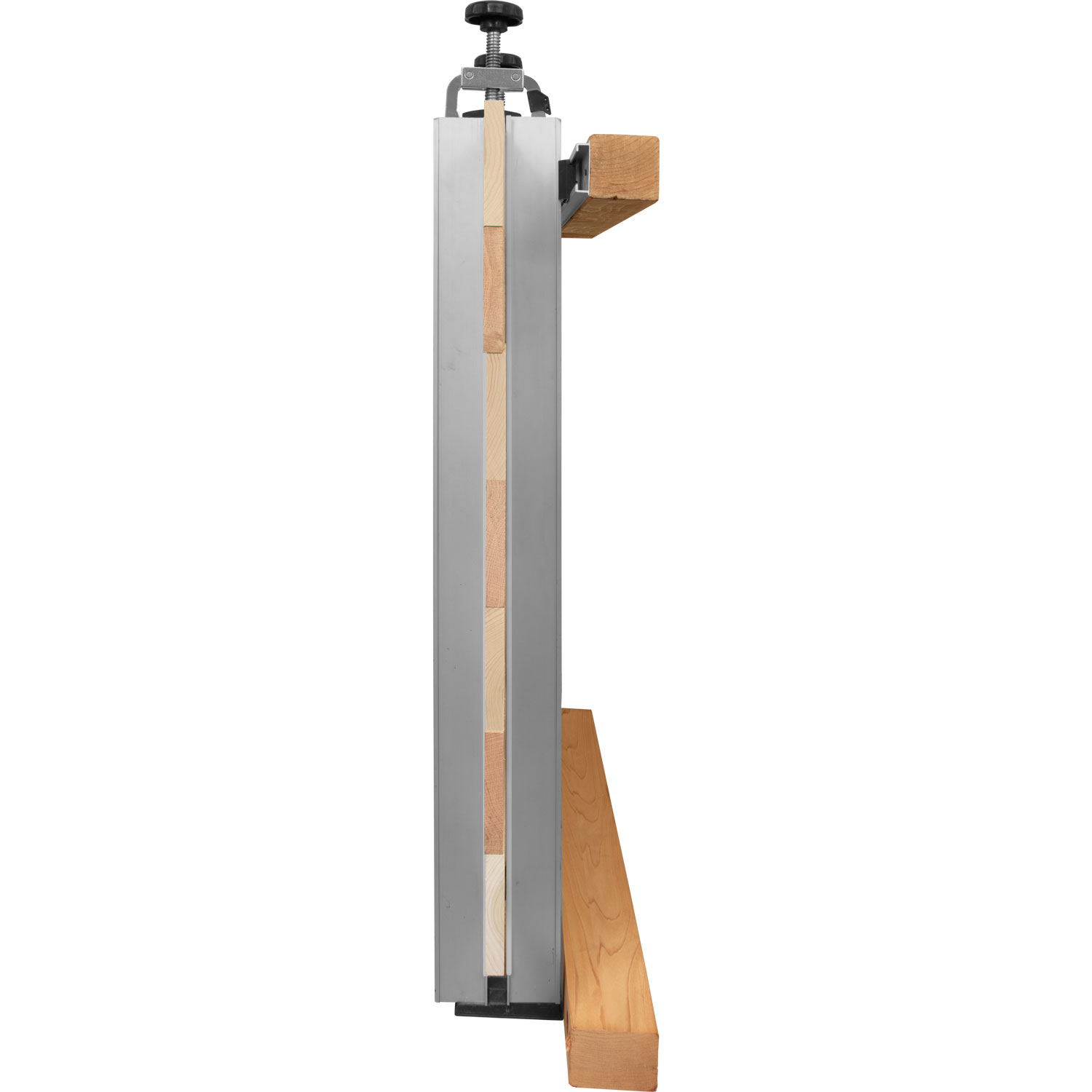

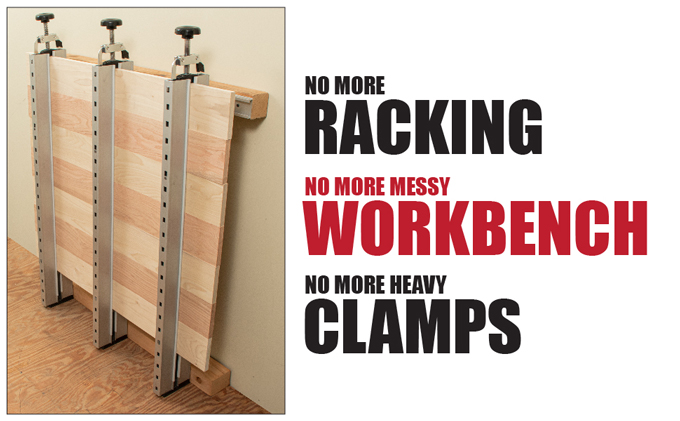

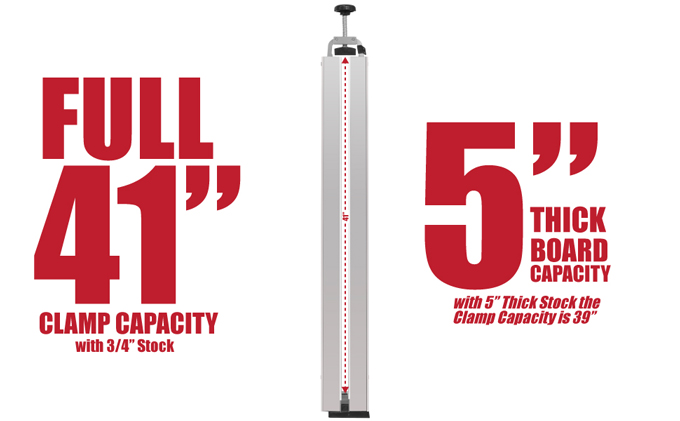

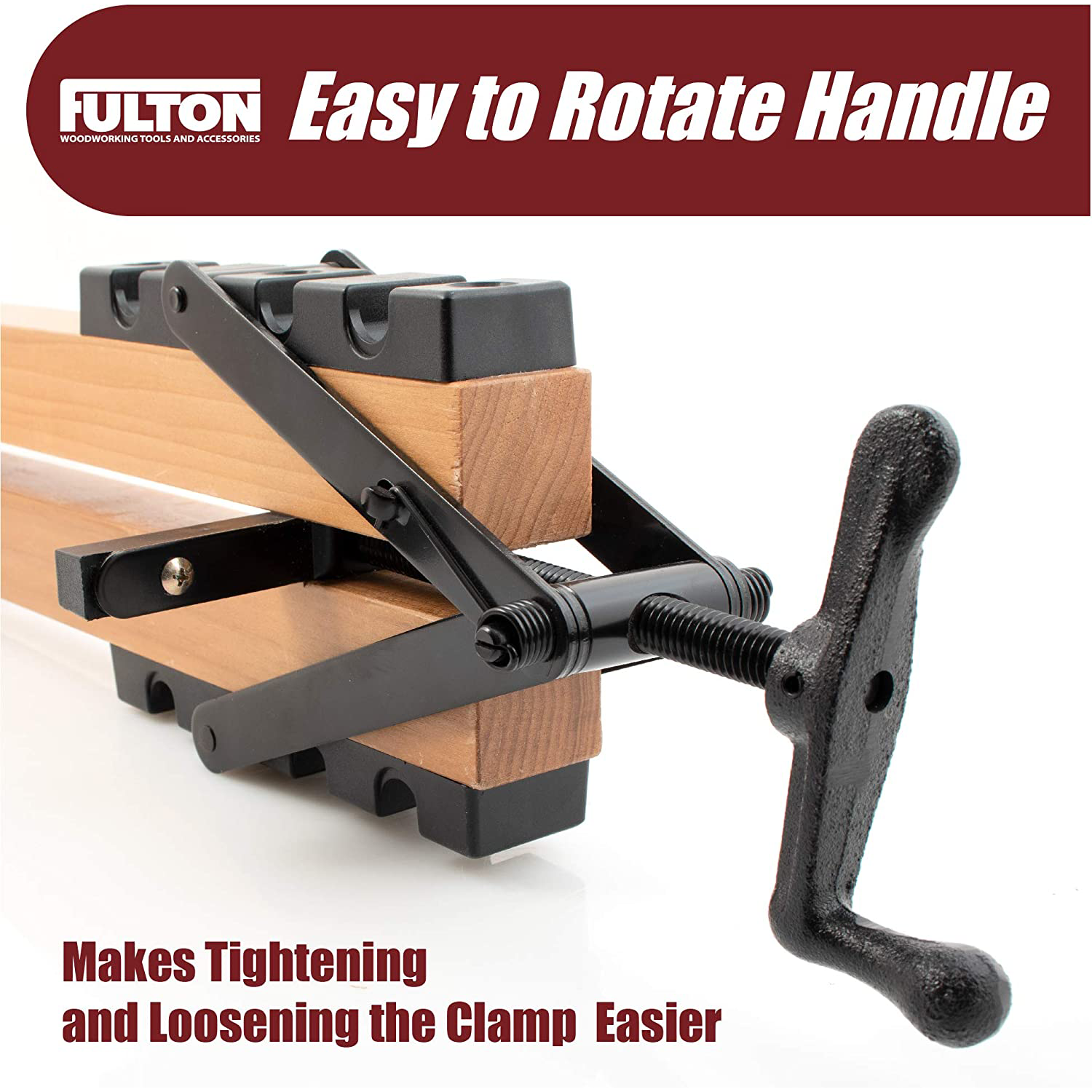

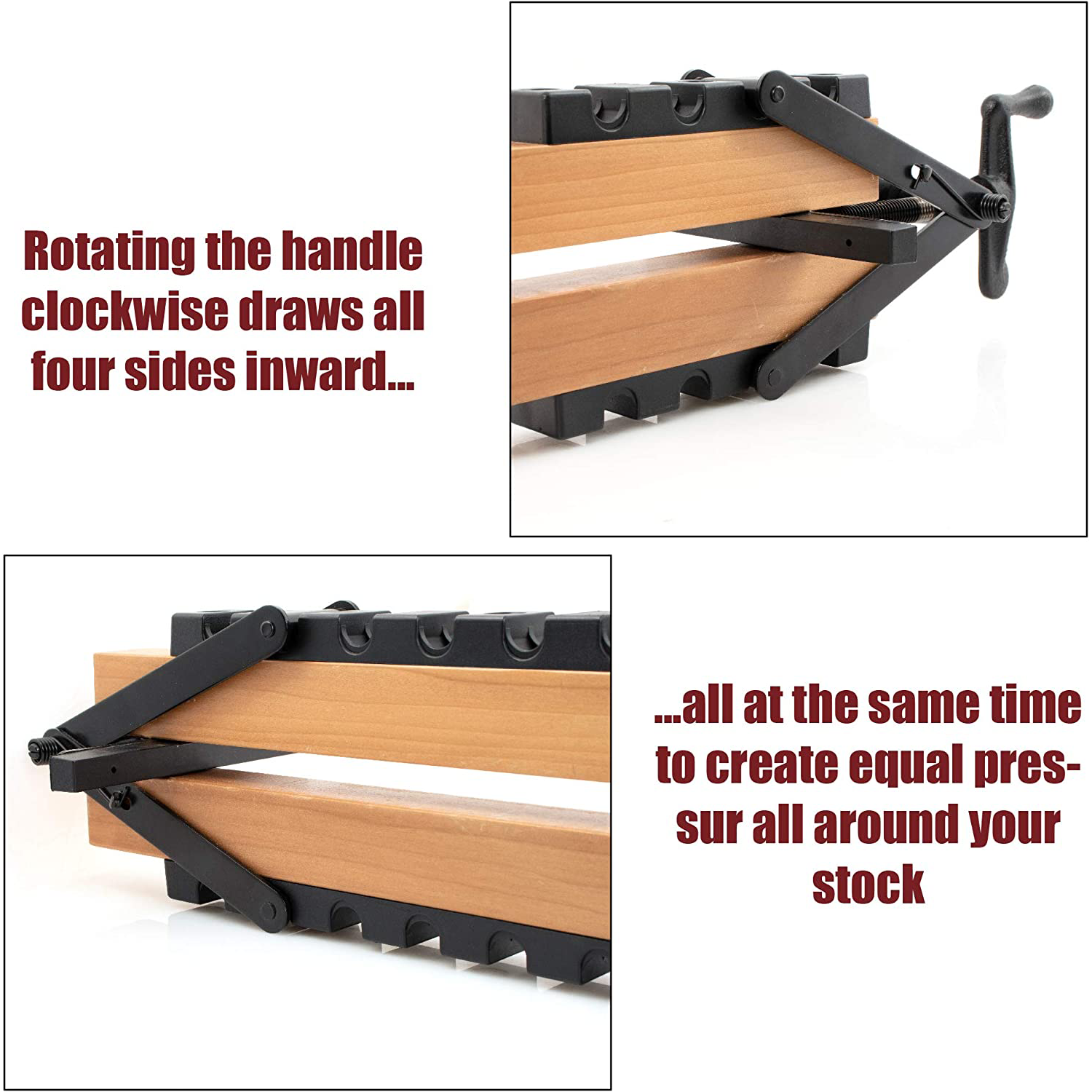

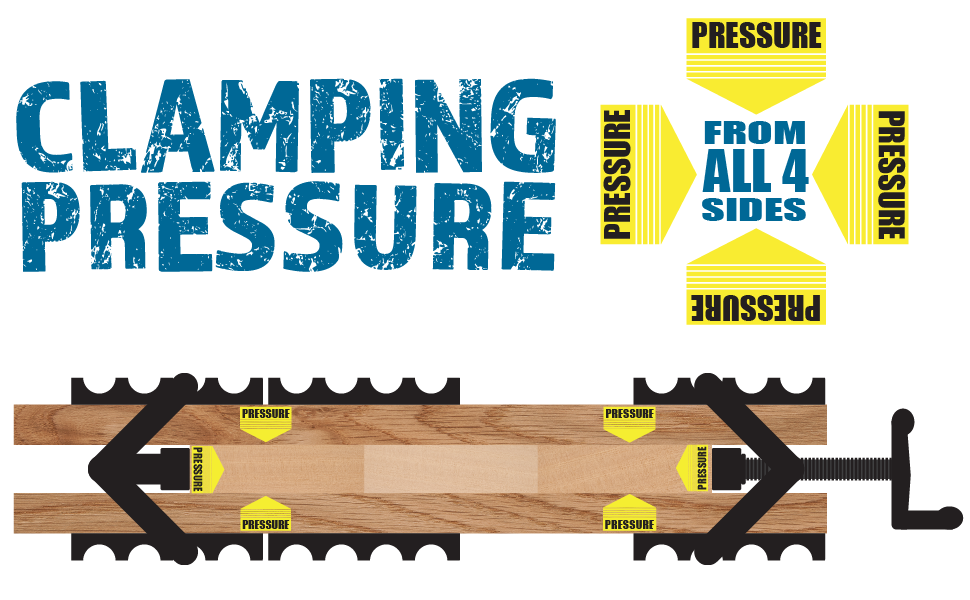

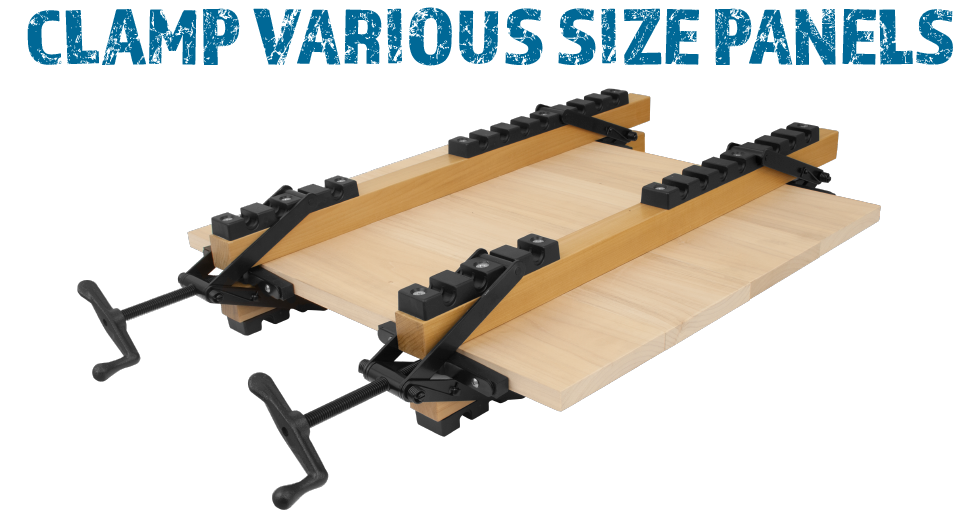

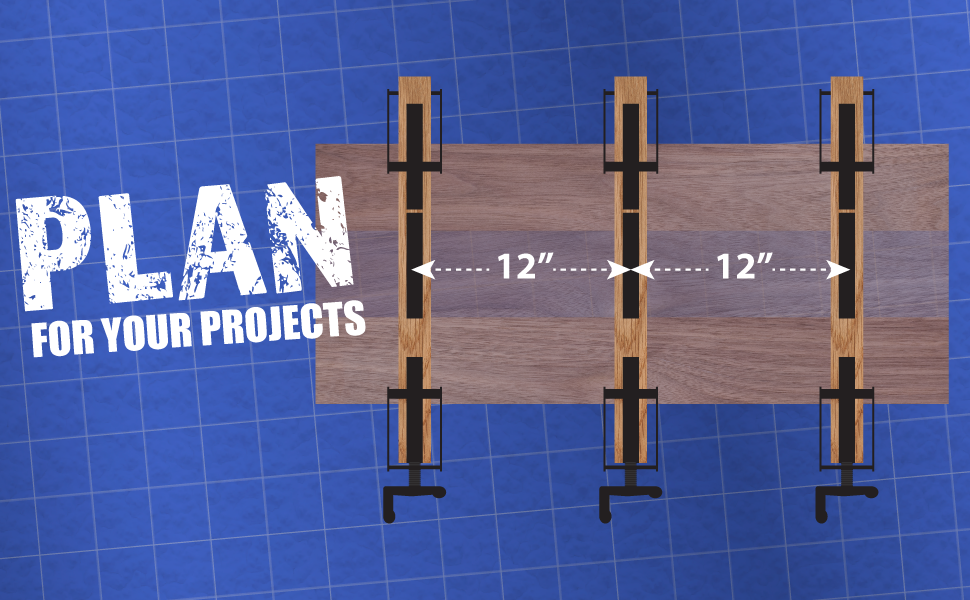

Equal Clamping Pressure on all 4 Sides! Clamping panels doesn't

have to be difficult. This clamp system is designed for the sole purpose of

clamping panels using pressure from the top, bottom and sides all at the same

time! Features:

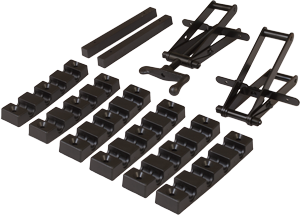

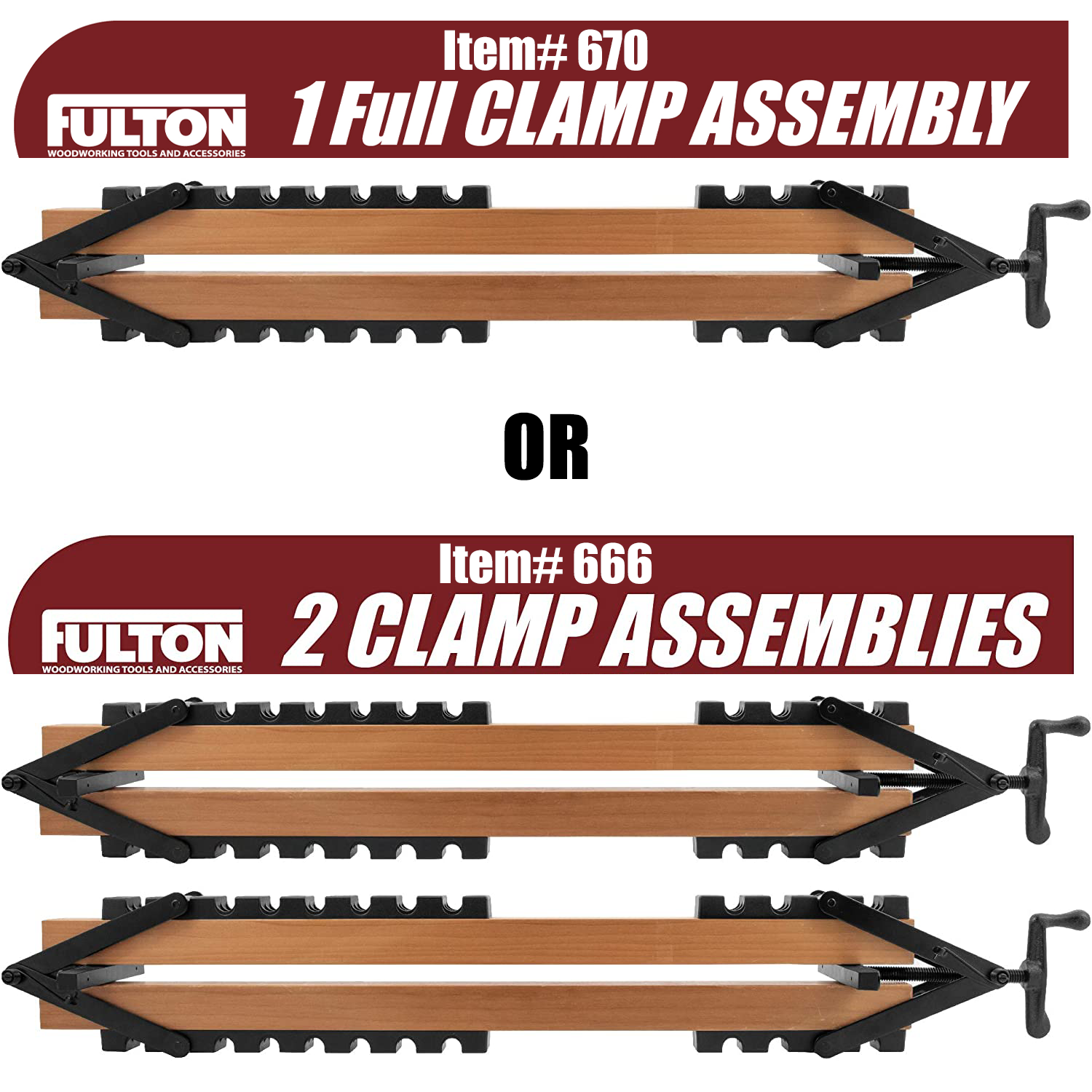

#670 Includes

#666 Includes

|

|||||||||||||||

|

||||||||||||||||

|

California

Residents:

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||

|

The 4 Way pressure notched bars are perfect for holding the steel clamping assemblies on the 4 Way Pressure Clamp in place for optimal clamping pressure from all 4 sides. Made from a durable composite resin material. Four notches for maximum adjustability. Mounting screws not included. Features:

|

|||||||||||

|

||||||||||||

|

California

Residents:

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||||||

|

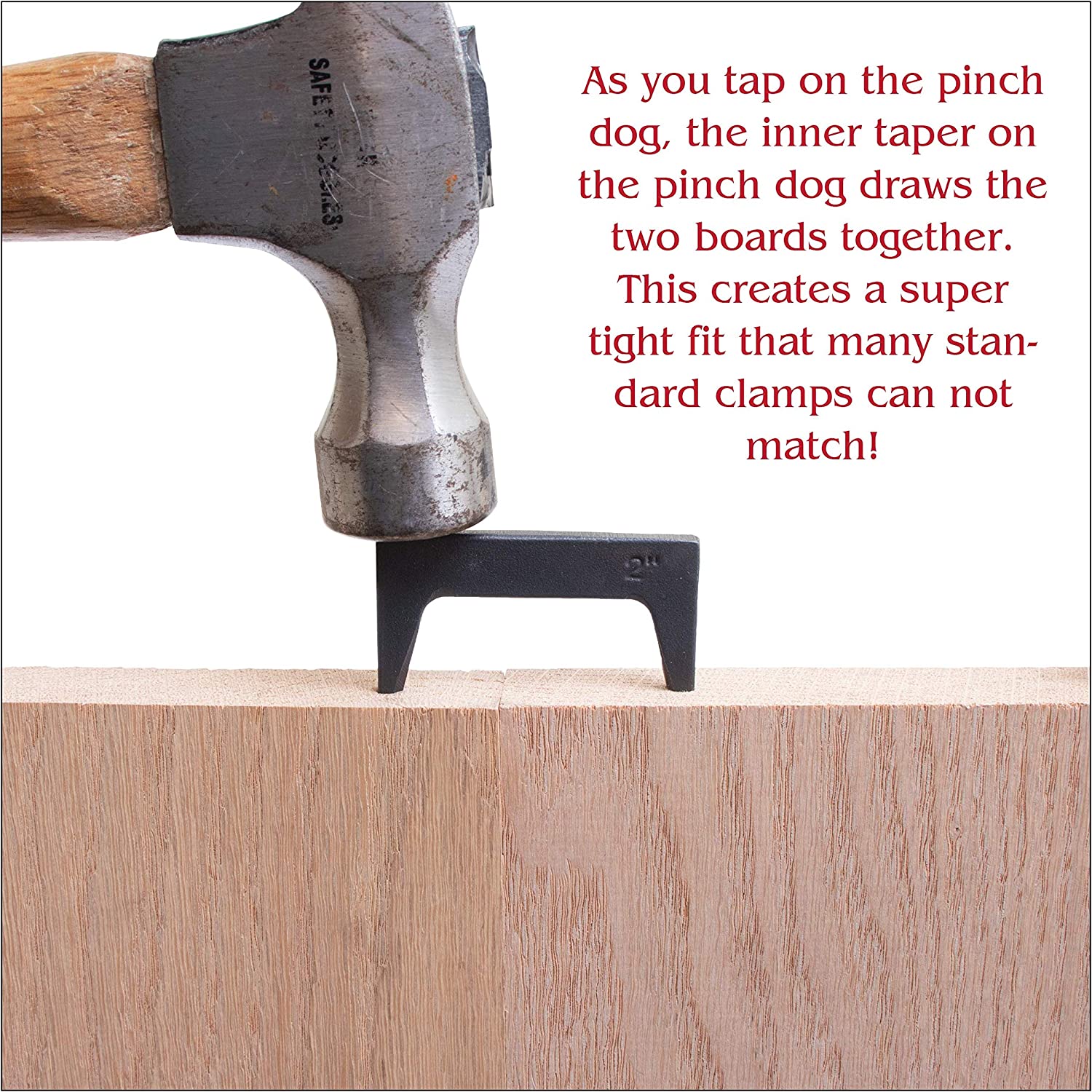

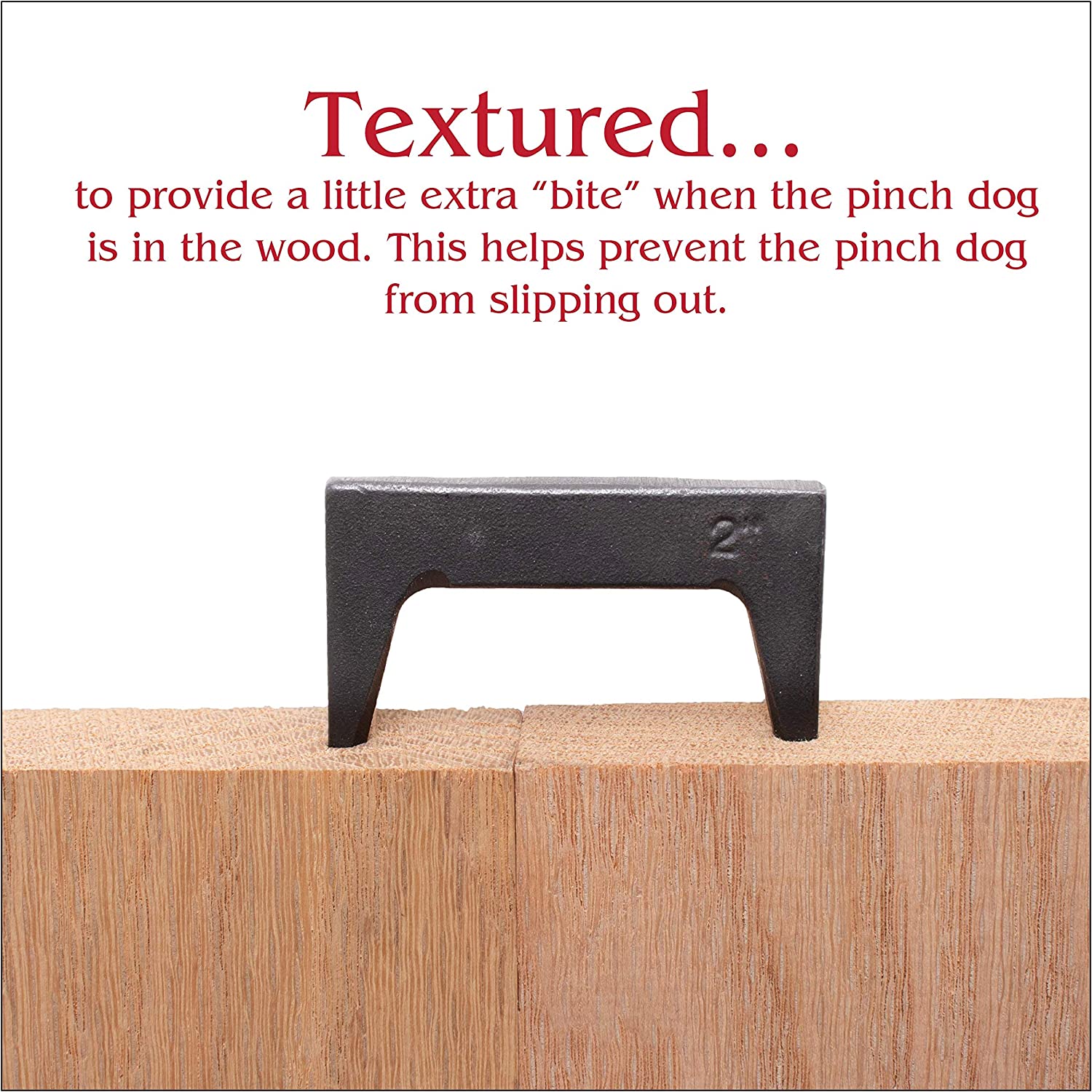

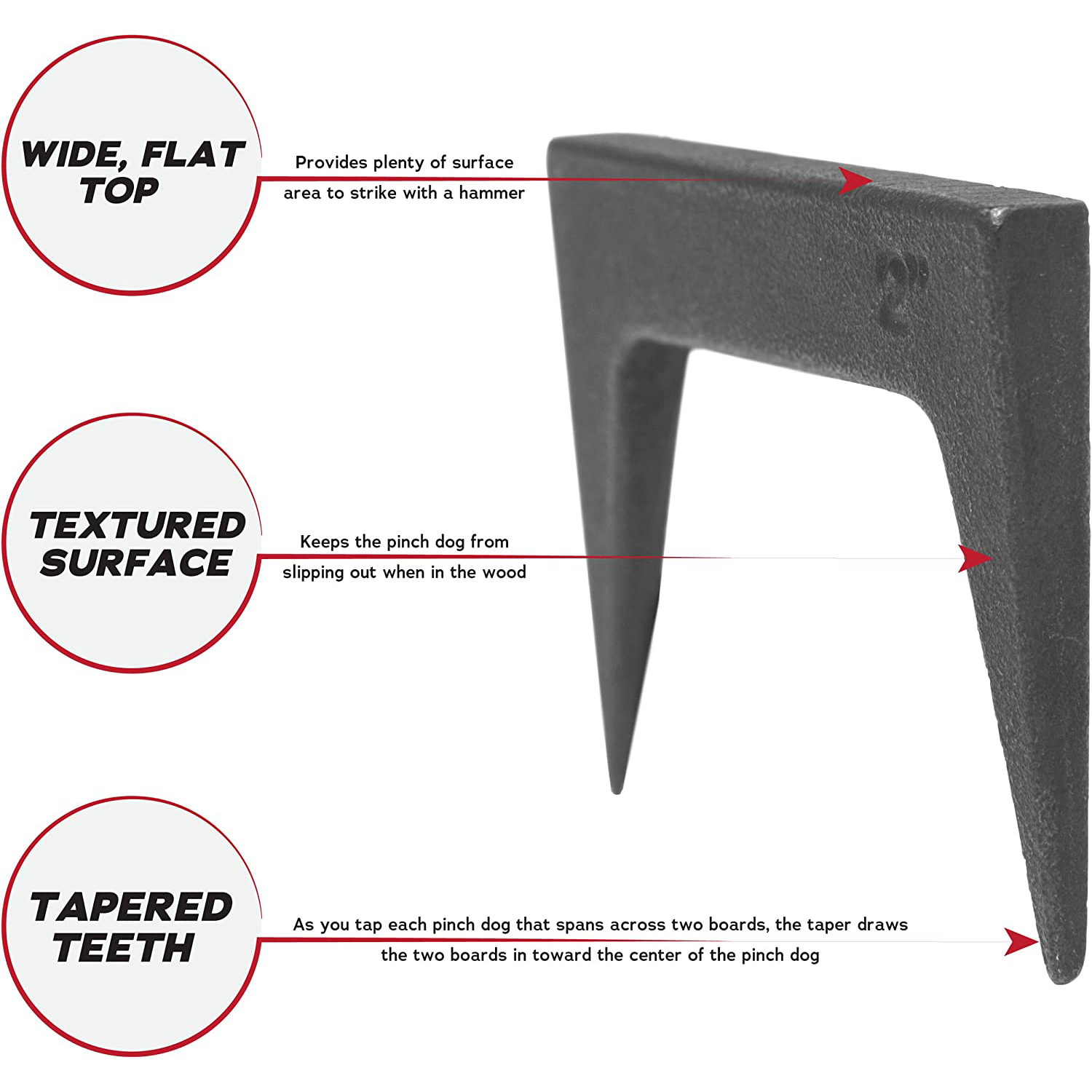

As the old saying goes; “you can never have too many clamps” if you’re a

woodworker. This holds especially true when it comes to achieving near seamless

or tight fitting joinery. While using long bar clamps or pipe clamps to glue up

panels will work, sometimes you may need a helping hand or “pinch” in certain

cases to get the seem just right. Using pinch dogs to pull your or “pinch” the

panel joint together is an old tried and true method that is still commonly used

today.

Features:

|

|||||||||||||||

|

California Residents:

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

Equal

Clamping Pressure on all 4 Sides

Equal

Clamping Pressure on all 4 Sides